Customised control system streamlines the process

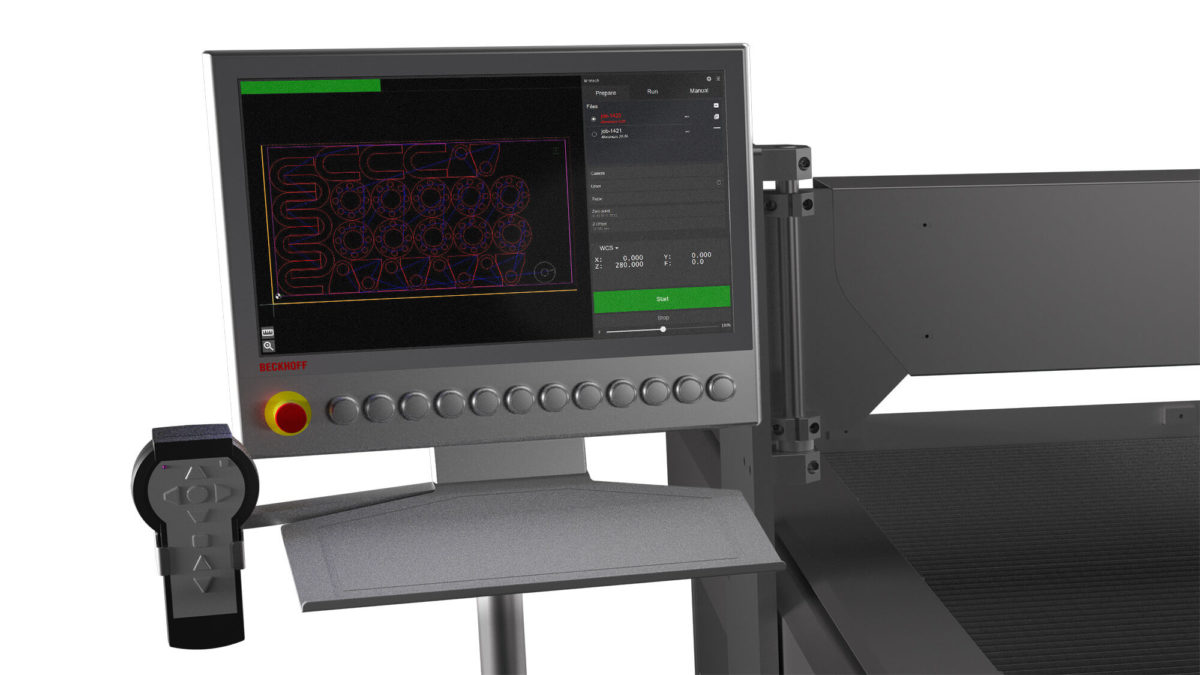

Kimtech’s waterjet cutting equipment is now even more user-friendly and efficient. A new control system from Beckhoff and a completely newly developed HMI, specially designed and adapted for waterjet cutting, facilitate the operator’s work and increase control. The system is built around the latest version of the Windows operating system, which allows the waterjet cutting machine to be easily integrated into the company’s existing IT solution. The system also offers the option of remote support and future updates online.

- Windows-based

Facilitates implementation in the company’s existing network. - New HMI/interface

New interface specially designed for waterjet cutting. Makes it easier for the operators and streamlines the process. - Point and Go, and Multi-Touch

The graphical presentation of the cutting has features such as Point and Go and Multi-Touch for zooming. The programs can easily be rotated in the interface if the sheet does not end up completely straight. - Timers

Built-in timers for automatic measurement of efficient cutting time, sand consumption and cutting tools give the operator full control over the process. - Job queue possible

Multiple jobs with different settings can be entered at the same time and then run in accordance with the queue list. - Remote access

Remote support is possible if the machine is connected to the internet. Help from Kimtech is then a push of a button away for the operator. The machine can also be updated online - App control

See how much time a program has left and get notifications if the program has stopped or is ready through the app. Facilitates unmanned operation of the cutting machine.