About us

Kimtech was founded in 1980 by Sven Kimblad. We initially delivered pumps and cutting heads to other machine manufacturers, but since 1988 we have developed and manufactured our own complete waterjet-cutting systems at our base in Järfälla, near Stockholm.

Quality

Knowledge

Service

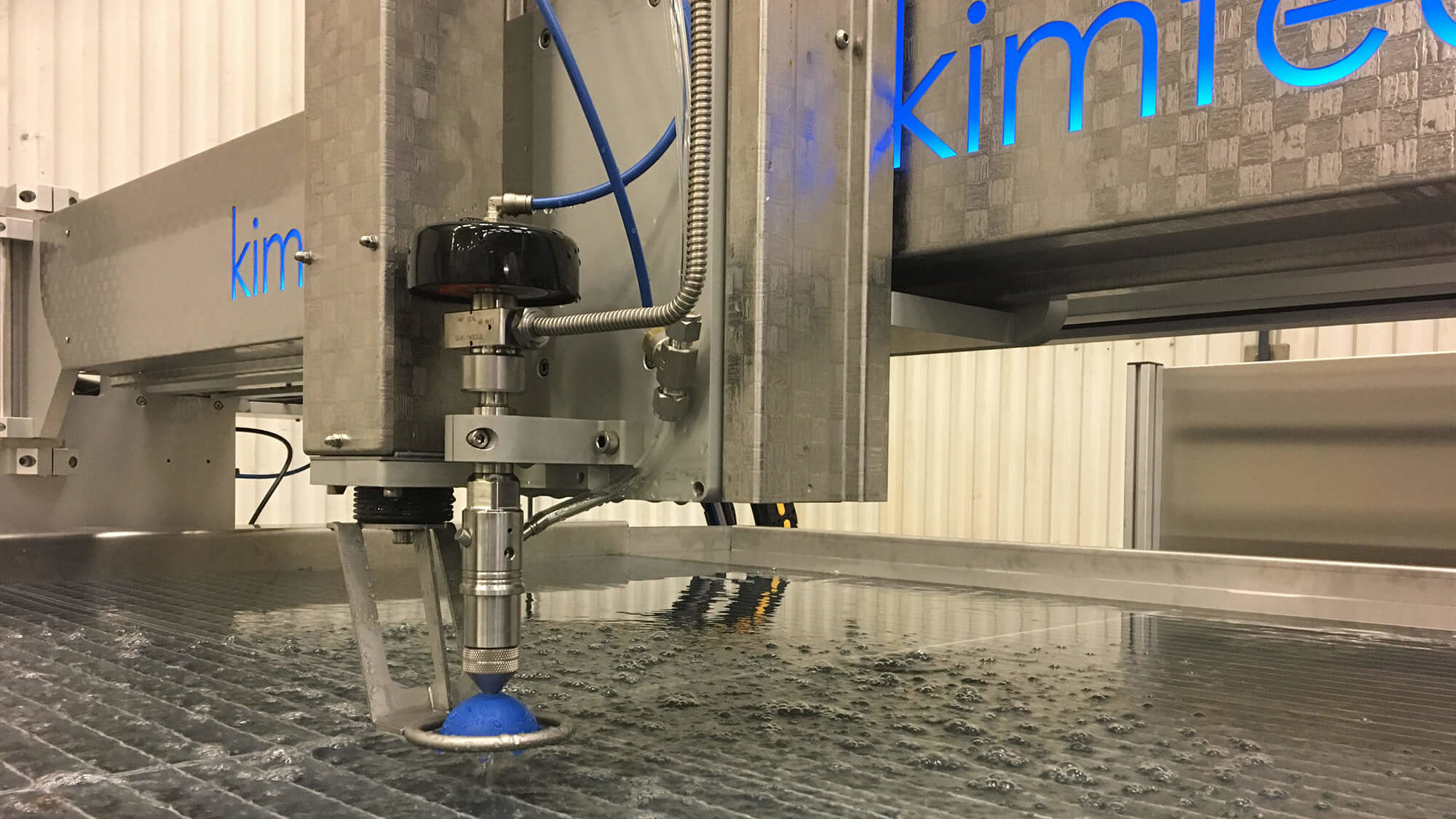

Maximum quality from the smallest component

Kimtech’s story began with the marketing of high-pressure waterjet products from Flow, the world-leading brand we still use for our machines. During the 1980s the water-cutting technique was developed, and had a big breakthrough when contour-cutting of nappies began. From the very start the technique was only suitable for softer materials such as nappies, paper, plastic and thin plywood. When abrasives were then added in the form of sand the scope of use was broadened. In the process Kimtech focused on its own manufacture of cutting machines that apply abrasive waterjet cutting.

Our brand name is based on the company’s full name Kimblad Technology AB, and we are now a leading supplier of waterjet-cutting systems in Sweden. We have delivered over 300 machines, and some of our oldest equipment, which has been in operation for over 40 years, is still doing well.

We have customers in many industries, and we also have the confidence to deliver to extremely sensitive operations such as nuclear power plants, the Swedish Armed Forces and the Swedish Prison and Probation Service – all of whom have extremely stringent requirements as regards safety and availability.

Paper mills are also important customers for us, and we supply them with pumping and cutting technology. The mills use waterjets to edge-cut paper rolls, and a stoppage anywhere in the production chain, including edge cutting, affects the entire line and can cost several million kronor an hour – something we are well aware of.

At our manufacturing unit in Järfälla we keep a complete stock of spare parts, so as to quickly be able to resolve service issues and minimise production downtime. We always want to be to hand for all our customers.

Kimtech’s team consists of engineers with very long experience of waterjet-cutting technology. As we develop our own machines we know them and the systems they are made up of down to the smallest detail. We also have service partners nationwide, to realise our ambition of fast on-site service. Our main goal is 100% satisfied customers.

Honorary award of Entrepreneur of the Year

Sven Kimblad has been named Entrepreneur of the Year in Järfälla Municipality, where Kimblad Technology AB has always been based. We are honoured to be recognised for our innovations, sales successes and collaboration with institutes of technology.

Milestones

Since Kimtech’s inception in 1980 there have been major and momentous developments within both the industry and the company. The following are some memorable years:

The company Kimblad Technology AB was started by Sven Kimblad. Under the name Kimtech, cutting-technology components from the Flow brand were delivered to other machine manufacturers.

Kimtech manufactured its first abrasive cutting machine. It was a machine with a cutting surface of 0.5 x 0.5 metres that was intended for prototype manufacture and delivered to one of our biggest customers, Outokumpu PSC Nordic in Degerfors.

Kimtech built its first waterjet-cutting machine using linear motor technology. We were one of the first manufacturers in the world to use the new, advanced technology.

We delivered our first machine to Norway. Norway is now a very important market on which we have so far put about 100 machines into operation.

The workshop area at our facility in Järfälla was doubled, thanks to a new hall.

Sven Kimblad was named Entrepreneur of the Year in Järfälla, thanks to stable success.

We manufactured our first waterjet-cutting machine, with a pressure of 6 000 bar. The technology was available earlier, but there were some problems. In 2011 we deemed it to be sufficiently tested and quality-assured – ready to use for our deliveries.

Our biggest waterjet-cutting machine hitherto was delivered to a customer in Belgium. The dimensions were 5×24 metres.

Our customer Bergs Mekaniska in Molkom bought our second record-sized machine, which measured 4×24 metres.

Plans for further expansion after the purchase of additional land.

Our new website was launched.