- Adapted for 3×1.5m sheets and 2x6m sheets

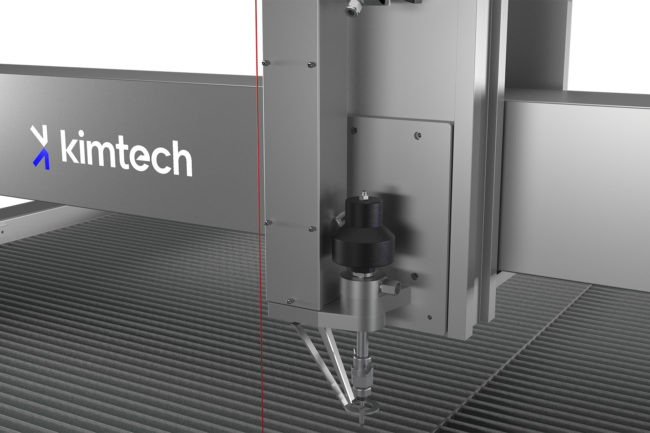

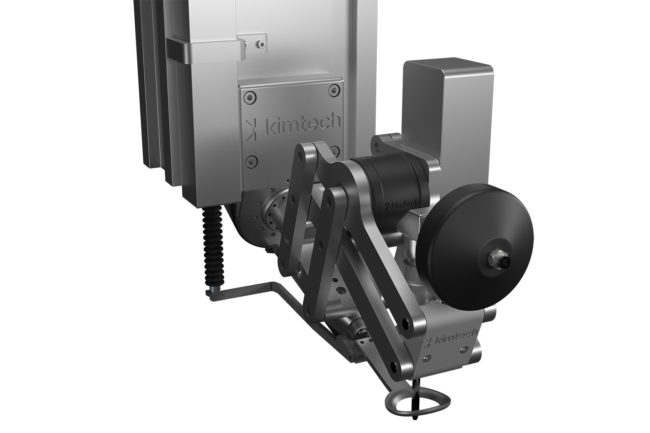

- Possibility of 5-axis cutting head – tilter.

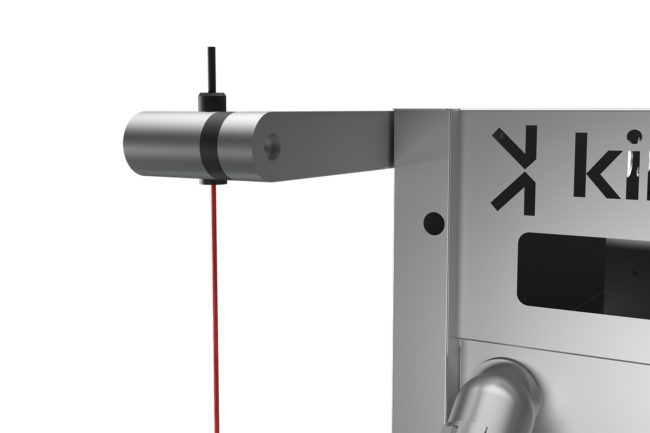

- Possibility of automatic height retention

- The control system is specially adapted for waterjet cutting

- Machine stand made of high-strength extruded aluminium profiles.

- Ergonomic control panel

- Ball-screw drive for all axes

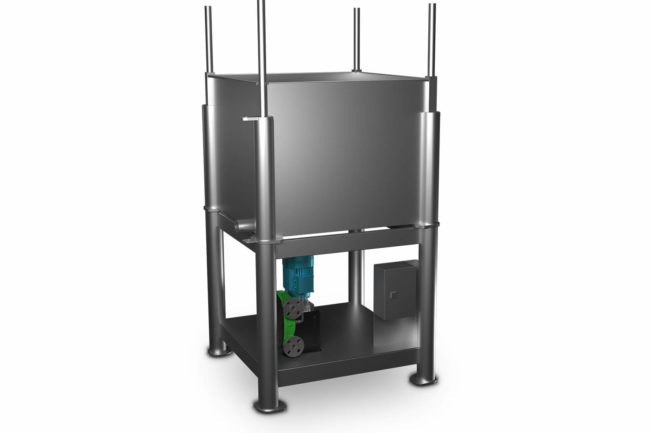

- Stainless-steel water tubs